Industries We Serve

china crusher provider

To continuously ideate, innovate and implement, to evolve with the needs of the industry and create products that add value to the mineral processing sector.

Build Your Dream

25 Years Of Undefeated Success

“It is our goal to set standards for the industries we serve by following these principles and thereby accomplishing our quest for excellence.”

512+

Successfully Project Finished.

25+

Years of experience with proud

200000+

Production square meters

960+

Skilled workers

Crusher series

Stone Crusher

Production Capacity:1-2200t/h

Max Feeding Size:125-1500mm

Processing Materials:200+ Materials

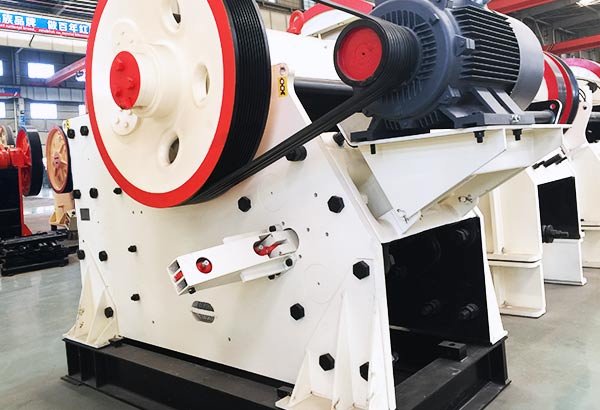

Jaw crusher

Feeding size:≤1500mm

Production Capacity:1-2200t/h

Output Size:10-400mm

CJ Series Jaw crusher

Feeding Granularity:120-1500mm

Production Capacity:1-2200t/h

Feed Opening:150×250-1600×2100mm

Cone Crusher

Single-cylinder Hydraulic Cone Crusher

Feeding Granularity:≤300mm

Production Capacity:30-860t/h

Feed Opening:150×250-1600×2100mm

Multi-Cylinder Hydraulic Cone Crusher

Feeding Size:≤326mm

Processing Capacity:72-1100m³/h

Hydraulic Cone Crusher

Feeding Granularity:≤314mm

Production Capacity:27-1814m³/h

Compound Cone Crusher (Symons)

Feeding size:≤314mm

Production Capacity:45-1814m³/h

Warranty:12 Months

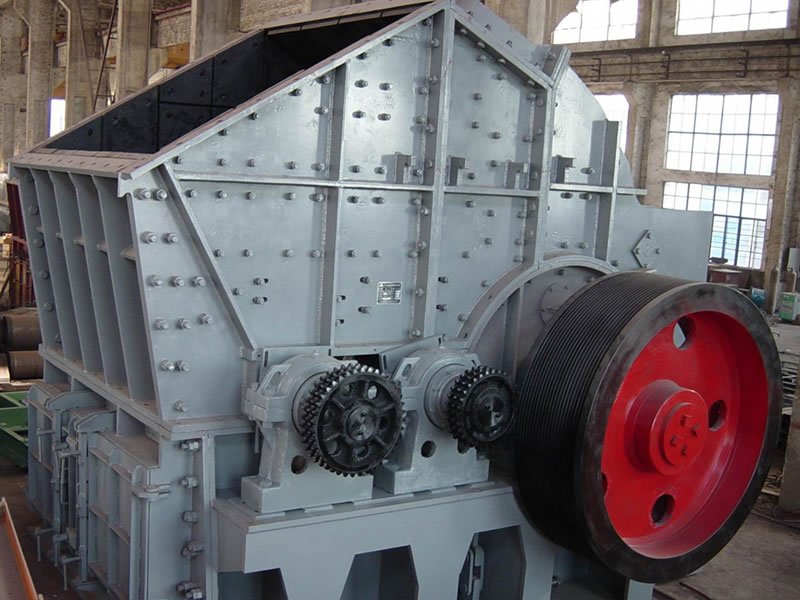

Hammer Crusher

PCZ Hammer Crusher

Feeding size:≤350mm

Production Capacity:5-150m³/h

PC Hammer Crusher

Feeding size:≤350mm

Production Capacity:5-150m³/h

PCX Hammer Crusher

Feeding size:≤350mm

Production Capacity:5-150m³/h

Impact Crusher

Standard impact crusher

Feeding size:≤800mm

Production Capacity:30-800t/h

CI series impact crusher

Feeding size:≤800mm

Production Capacity:30-800t/h

HX impact crusher

Feeding size:≤800mm

Production Capacity:30-800t/h

HD german Impact Crusher

Feeding size:≤800mm

Production Capacity:30-800t/h

Sustainability

WHAT WE OFFER

World leading heavy machine company serving metallurgy cement , construction , refractory materials and ceramic industry and other sectors.

We Follow Best Practices

In pursuit of excellence, Henan Hongxing Mining Machinery promises that we’ll always provide high-quality products, professional technologies and heartfelt service to help customers create more profits and improve ecological construction through practical actions. Trust us, and we will never let you down.

- Sustainablility

- Project On Time

- Modern Technology

- Latest Designs

Global partners

Request a Quote

Learn More From

Frequently Asked Questions

Jaw crushers are sometimes also referred to as “rock breakers,” which speaks to their brute force. They are almost exclusively used as primary crushers because they excel at breaking up some of the largest and hardest materials into more manageable pieces for further reduction by different crushing equipment. Jaw crushers have a multitude of advantages, including:

- Ability to handle many different types of materials—from hard granite to reclaimed asphalt pavement (RAP) and more—without displaying as much wear and tear as primary impact-style crushers.

- Typically output minimal fine materials and dust.

- More efficient than primary gyratory crushers.

Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications, where some other primary crushing solutions do not fit.

Jaw crushers have been around for nearly 200 years and are one of the most “historic” crusher types. Because of this, jaw crushers have undergone many technological advances through the years to become more durable and to improve their movement to reduce choking and increase operational speed. These design tweaks over time have perfected a machine that’s simple enough in its working principle that it may never become obsolete.

Today, two main jaw crusher configurations can be seen from the major equipment manufacturers. They differ based on how the swing jaw moves, though their output is similar.

Double Toggle—Blake Type or Overhead Pivot Movement

Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, Eli Whitney Blake) have long been the standard for crushing hard and abrasive rocks, as well as sticky feeds. These jaw crushers have high energy-efficiency. The overhead pivot design further reduces wear and tear on crusher faces versus the Blake style.

Single Toggle—Overhead Eccentric Movement

More compact than double toggle designs, the single toggle movement jaw crusher was at one time unable to accept such large feed sizes, though it can typically run faster. Technological innovations solved the feed size issue, and now these machines are popular for how quickly they work. They do experience more wear and tear than the double toggle style crushers, but wear parts are widely available and economical.

Different jaw crusher designs will operate slightly differently, but how they work is similar across the board. All jaw crushers reduce large sized rocks ore, or other materials by a compression action. A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on the feed material by pushing it against the stationary plate.

The space at the bottom of the V-aligned jaw plates is the output gap that dictates the size of the crushed product from the jaw crusher. The rock remains in the jaws until it is small enough to pass through the gap.

While jaw crushers may always be a smart primary crusher stage choice for many operations, it’s true that newer cone crushers are increasingly taking their place due to versatility. Cone crushers and jaw crushers both work by compression, reducing materials by squeezing them until they break apart.

The benefit that cone crushers offer over jaw crushers is their ability to output a more cubical product similar to impact crushers. Cone crushers have traditionally been used as secondary and sometimes tertiary crushing stations.

As far as answering whether one type of crusher is better than another, context is key. Everything comes down to what your production needs and goals are.